Quality Control

Both our facilities have been certified for compliance with quality management system standards. Our flagship Paradeep plant is certified under ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, ISO 50000:2018 and ISO/IEC 17025:2017. Our newly acquired Goa facility has been certified under ISO 45001:2018 and ISO: 14001:2015.

We are committed to ensuring quality and product safety at every step of our production process — from procurement of raw materials till the finished product is packed and ready for distribution. We have a state-of-the-art quality control laboratory at both facilities where we rigorously test our raw materials and finished products against defined quality parameters.

Through sample testing, we ensure that the colour, odour, appearance and nutrient content of our products comply with quality and safety standards. We also send samples to NABL-accredited and national laboratories for additional testing. Our QC laboratories are well-equipped with advanced machinery such as an atomic absorption spectrophotometer for analysis of heavy metals, an autoanalyser for ammonia and phosphorus pentoxide, and a UV-spectrophometer.

Quality Control Measures

Assembly line product inspections for quality control

Periodic batch-wise inspections for consistency

Sample surveys at distribution sites to ensure proper transportation and storage

Regular training programmes on quality control and process safety

Process-oriented approach to minimise accidents

World-class R&D team dedicated to product development and scaling up processes

Safety Processes

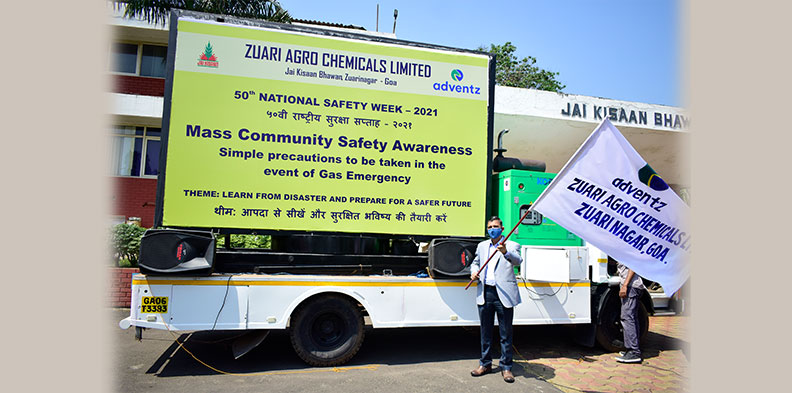

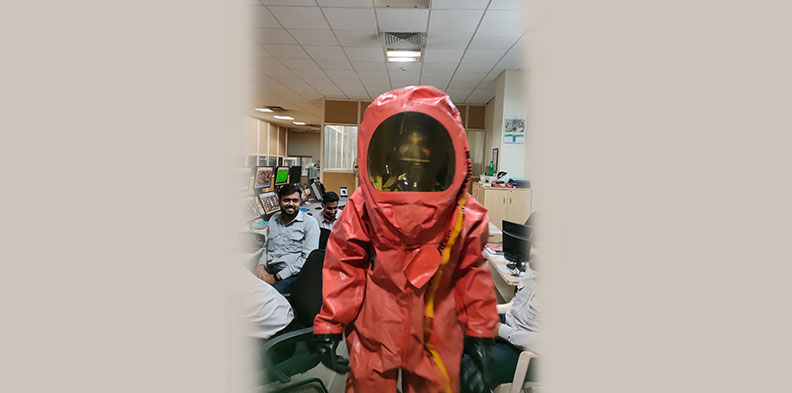

To ensure a safe working environment at our facilities, we follow a stringent and process-oriented approach to minimise the risk of accidents and injuries. Each plant has a dedicated safety department that monitors all aspects of occupational safety.

Over the years, we have been appreciated for our excellent safety practices:

- 20th Annual Greentech Effective Safety Culture Award for exemplary initiative & practices in the field of developing an effective safety culture

- Kalinga Safety Excellence Award under Platinum Category in chemical & fertilizer sector 2020 for exemplary efforts in maintaining best safety practices

- Fire Safety Certificate from Govt. of Odisha Fire Service (valid till 4th Jan, 2024)

- ‘Premium Membership’ certificate from British Safety Council UK (valid till 15th March, 2025)

R&D

We have a world-class research and development team at our facility in Paradeep, Odisha. Since 2014, our R&D centre has been recognised by the Department of Scientific and Industrial Research under the Government of India. Our dedicated R&D team focuses on creating innovation and delivering the best-in-class products to our customers.

The core functions of our R&D team are:

- Developing new products

- Scaling up processes from lab scale to plant scale and establishing standard operating procedures

- Identifying raw materials such as rock phosphates, ammonia, sulphur, plant nutrient additives, etc.

- Exploring new applications for by-products

- Conducting pre-feasibility performance studies on raw materials

- Developing and validating analytical methods

- Developing customised products according to FCO norms